MG2 containment systems: when technology and flexibility go hand-in-hand

Containment: what it’s for and how it can be achieved

The main purpose of containment systems consists in avoiding the product release, thus assuring operators and environment protection from the exposure to potentially toxic substances. Besides, isolators can also be utilized to protect the product from both external contamination and environmental unsuitable conditions, by keeping constant some parameters such as temperature and relative humidity level.

In favour of the operator’s safety, some OEL (Occupational Exposure Limit) thresholds have been defined, establishing the maximum product concentration level per cubic meter under which an operator being exposed for 8 hours per day does not run any risk. Based on the product to be handled the customer defines the best OEL level. Such limits are typically managed by means of a classification into OEB (Occupational Exposure Band) classes, which determine the admissibility range. For example, OEB 5 class covers the range between 0,1 µg and 1 µg of product per cubic meter.

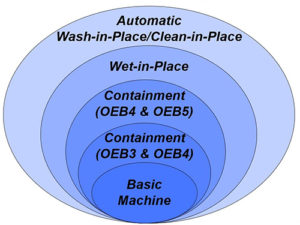

The higher classes (OEB4 and OEB5) are required for strongly active and/or toxic pharmaceutical products, such as those utilized for cancer treatment. MG2 machines can be equipped with different systems suitable for all OEB classes, based on the containment strategy required by the product. For example, the utilization of isolators equipped with inflatable gaskets, gloves and RTP (Rapid Transfer Port) is of primary importance to satisfy the higher classes requirements (OEB5/OEB4).

MG2 answer to innovative pharmaceutical production trends

The reason why MG2 is investing in the study and in the development of such heterogeneous systems is based on both the increasing number of projects which foresee the adoption of containment strategies, and systems to comply with the more and more restrictive criteria in terms of control and safety followed by the pharmaceutical companies.

In fact, if on the one hand the adoption of containment strategies is a practice which has been utilized for long time to handle highly active products, during the last years many companies put into force in-house regulations foreseeing the compliance to high containment classes even when less critical products are to be handled with new production lines.

This willingness is going hand in hand with another important trend giving priority to the adoption of containment system on the machine instead of the utilization of personal protective equipment for the operator (PPE – Personal Protective Equipment), which are usually very expensive and poorly ergonomic in that they considerably hinder free movements.

This choice also makes it possible to take considerable advantages in terms of production environment conditioning, in that it allows to keep high air quality in smaller areas than it would happen by utilizing machines being not equipped with containment systems.

FlexaLAB in containment version in MG2 Pharma Zone

FlexaLAB in containment version in MG2 Pharma Zone